Shenzhen, China

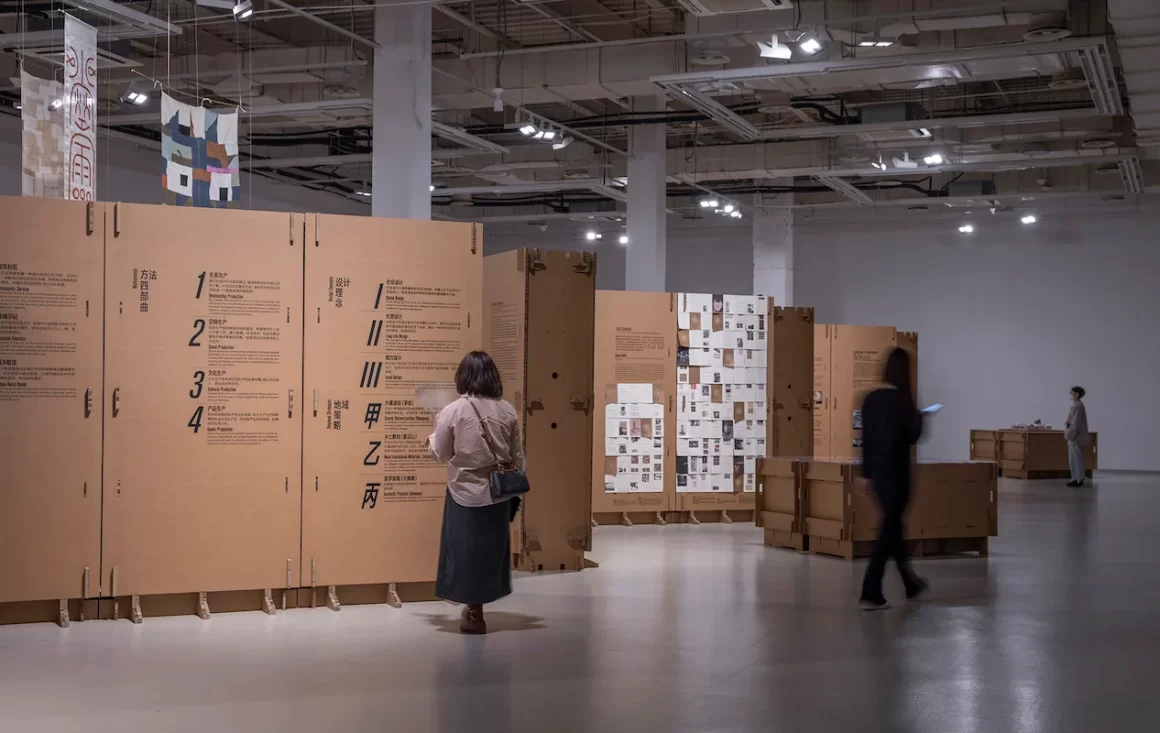

Assembling highly recyclable corrugated cardboard with a unique mortise and tenon structure to form walls and stands, LUO Studio has proposed an exhibition design that avoids construction waste for the exhibition “Back to the Future: Breaking the Time Barrier” at the OCT Art & Design Gallery in Shenzhen curated by Zuo Jing and Wang Yanzhi.

Since the exhibition “Long Life Design: Thinking and Practicing” was held in the OCT Art & Design Gallery in Shenzhen and the Pearl Art Museum in Shanghai, curator Zuo Jing has been carrying out practices and research on sustainable design, hoping to present an exhibition with the concept of “Zero Waste.”

LUO Studio has also been exploring sustainability in design practices, and it was in such a context that a cooperation with the gallery was made possible.

The studio designed the setting for “Back to the Future: Breaking the Time Barrier” exhibition co-curated by Zuo Jing, using recyclable corrugated cardboard assembled with a unique mortise and tenon structure to form walls and stands.

Generally, much more attention is paid to the work before an exhibition, rather than what happens afterward.

Exhibition spaces are often temporary with a short life cycle, and the exhibition installation period between opening and dismantling is also extremely short.

For these reasons, a rapid, low-cost common method, for example, the use of light steel keels, gypsum boards, and latex paint, as well as other similar materials, is frequently adopted for the construction of exhibition settings.

However, at the time of dismantling, the construction must be demolished completely, resulting in a large amount of waste.

Corrugated cardboard is globally recognized as a highly reusable and recyclable material.

Particularly lightweight and environmentally-friendly, the material is also convenient for processing, moving, transporting, and assembling.

For these reasons, LUO chose it as the building material for the temporary exhibition.

In terms of display, the texture and color of corrugated cardboard match well with the exhibition theme, as well as the characteristics of the exhibits.

With corrugated cardboards as structural components, CNC cutting technique was used to make concave and convex edges, through which a structure of “mortise and tenon” was created, to form insert buckles of the cardboards.

Due to the low density of cardboard, it takes a shorter time for CNC cutting and processing, compared with other conventional building materials.

All 320 pieces of raw cardboard used for the exhibition were processed into 2,566 cardboard components in less than two days.

Such an efficient construction process benefits not only from the lightness of the cardboard material, but also from not requiring any assembly tools.

As the space is strongly defined by strong columns, they were used as the basic elements to create spatial order.

Radiating from the center of each column, four display walls are combined to form an X shape on the plane.

Each integrated X-shaped wall divides the space around each column into four isosceles triangular areas facing outwards.

Meanwhile, two halves of the “X-wall” in between the columns form an inward-facing rectangular space.

These two types of spaces satisfy the needs of dividing the exhibition into different sections for various curators, allowing for greater flexibility and orderliness.

The standard size of corrugated cardboard selected was 2.4 meters by 1.2 meters.

Since one set of “X-wall” consists of four pieces of walls extending from the center of a column in four directions, three vertical corrugated cardboards were connected horizontally to form one piece of wall with a width of 3.6 meters.

Moreover, untrained people can take over the work of professional constructors to assemble the cardboard.

The used corrugated cardboard can be disassembled and then reassembled and installed in different places serving the subsequent exhibitions.

Even after losing its function, discarded corrugated cardboard can still be recycled and reused by up to 96%.

Taking firmness into consideration, boards with two different thicknesses (15mm and 20mm) were selected, with a standard size of 1.2 meters long and 2.4 meters wide.

Exhibition methods in the form of graphics and texts are mostly screen printed and directly pasted on the cardboard, while others are fixed on the cardboard by nails.

Other exhibition equipment including LCD screens, tablets, mp3 players, and earphones, as well as physical objects, such as books and woodblock print templates, require special structural components in order to be fixed and well displayed.

Corrugated cardboard is relatively light compared to other conventional construction materials.

In order to stabilize the exhibition walls and stands, a number of construction measures have been carried out, such as installing supporting legs and skirtings.

Each 1.2 meter-wide module is raised 15 cm above the floor and is equipped with three plates as supporting legs.

Inside each module, a certain amount of space is reserved for setting a sandbox (existing props owned by Power Station of Art) as a counterweight, so that each single module has enough load-bearing capacity to ensure stability.

Furthermore, the 3.6 meter-wide walls formed by every three modules are connected with each other near the center of each column.

Environmentally speaking, the exhibition exemplifies the theme to “reduce, reuse and recycle,” and the construction of the exhibition space itself has become one part of the exhibits.

Project: Exhibition Design of “Back to the Future: Breaking the Time Barrier”

Architects: LUO Studio

Curators: Zuo Jing and Wang Yanzhi

Spatial Design & Construction: Luo Yujie, Lu Zhuojian, Wang Beilei, Hong Lun, and Liang Jiahui

Visual Designer: He Jianping

Collaborators: Bishan Crafts Cooperatives

Corrugated Cardboard Supplier: Kunshan Three Doves Paper Design Studio Co. Ltd.

Exhibition Space OCT Art & Design Gallery Architects: Studio 10

Client: OCT Art & Design Gallery

Photographers: Jin Weiqi and Sui Sicong